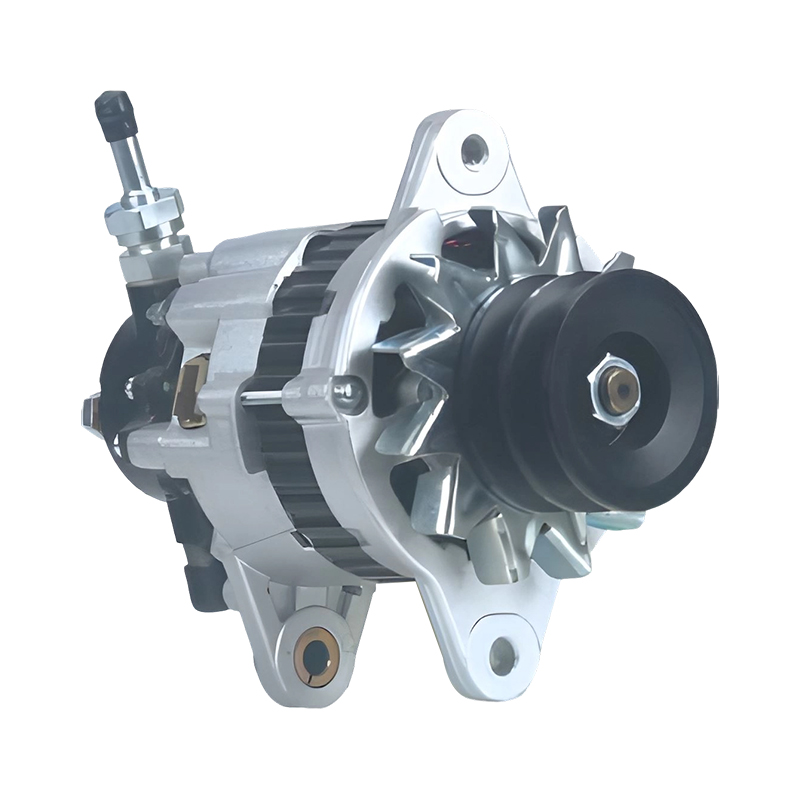

The ZKM32330 automotive alternator operates at a rated voltage of 24V DC system with a continuous output current of 80A, featuring an integrated internal voltage regulator. It is suitable for various ...

See DetailsWhat Is a High Output Car Alternator and When Do You Need One

Jan 05, 2026

Understanding What a High Output Car Alternator Is

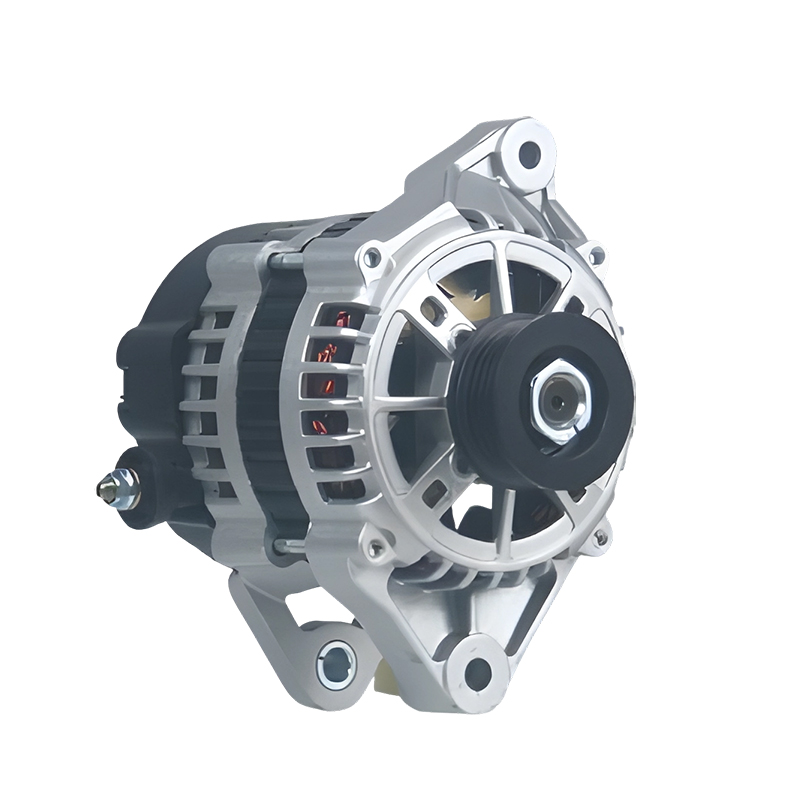

A high output car alternator is an upgraded charging component designed to produce more electrical current than a standard factory alternator. While a stock alternator is built to support original vehicle systems such as ignition, lighting, and basic electronics, a high output alternator is engineered to handle increased electrical loads created by aftermarket or heavy duty equipment. The key difference lies in amperage capacity, which allows the alternator to supply stable power without overloading or voltage drop.

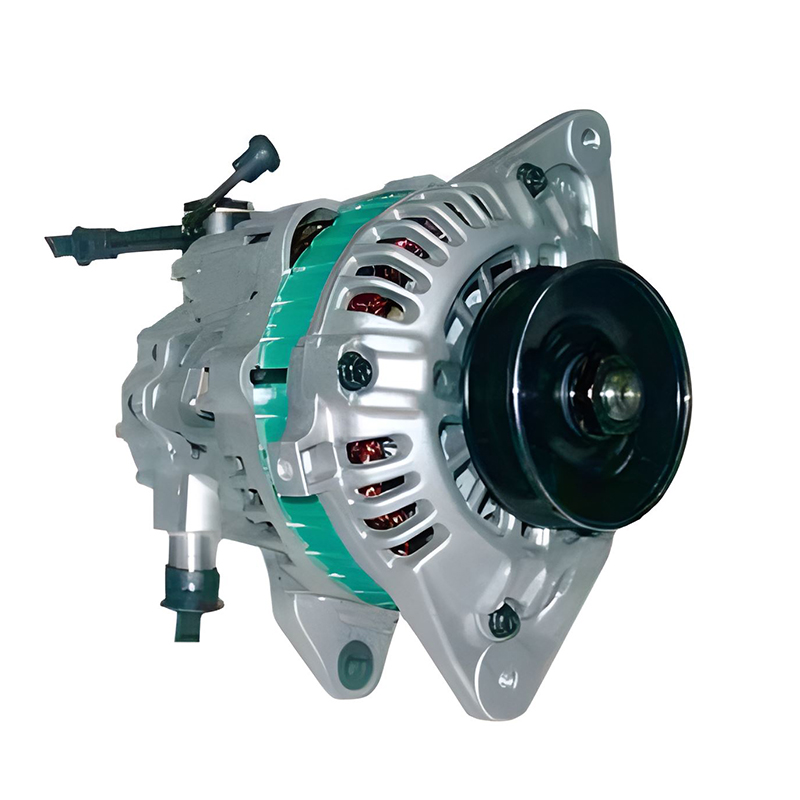

High output alternators use improved internal windings, upgraded stators, and enhanced cooling structures to maintain consistent performance under higher demand. This makes them suitable for vehicles where electrical consumption exceeds original design limits.

How a High Output Alternator Differs From a Standard Alternator

The practical difference between a standard alternator and a high output version becomes clear when additional electrical accessories are installed. Standard alternators are optimized for average driving conditions and moderate loads, while high output alternators are built to deliver sustained current at both idle and driving speeds.

| Feature | Standard Alternator | High Output Alternator |

| Amperage Capacity | Limited to factory load | Designed for increased demand |

| Idle Output | Often reduced | Maintains stable current |

| Heat Management | Basic cooling | Enhanced cooling design |

Common Situations Where a High Output Alternator Is Needed

A high output alternator becomes necessary when electrical consumption consistently exceeds what the original alternator can safely supply. This situation often occurs in modified or specialized vehicles rather than stock daily drivers.

- Vehicles with high power audio systems using multiple amplifiers

- Off-road vehicles equipped with winches, auxiliary lighting, or compressors

- Work trucks running inverters, refrigeration units, or mobile equipment

- Emergency or service vehicles requiring stable power at idle

Signs Your Current Alternator Is No Longer Sufficient

Electrical strain often appears gradually, and many drivers overlook early warning signs. When the alternator cannot keep up with demand, the vehicle may rely excessively on the battery, leading to reduced system stability.

- Dimming headlights when accessories are active

- Voltage drops visible on gauges or diagnostic tools

- Frequent battery replacement despite normal driving habits

- Electrical accessories cutting out under load

Benefits of Upgrading to a High Output Car Alternator

Upgrading to a high output alternator improves overall electrical reliability rather than simply adding more power. With sufficient current available, the charging system operates within a safer range, reducing stress on both the alternator and battery.

Key benefits include more stable voltage delivery, improved charging efficiency during low speed operation, and better support for long term accessory use. This upgrade also helps prevent overheating and premature alternator failure caused by constant overload conditions.

When a High Output Alternator May Not Be Necessary

Not every vehicle requires a high output alternator. If the vehicle remains close to factory configuration and does not operate power intensive accessories for extended periods, a standard alternator may continue to perform adequately.

Careful evaluation of total electrical load, driving habits, and accessory usage is essential before upgrading. Installing a high output alternator without real demand may offer limited practical benefit.

Key Factors to Evaluate Before Choosing a High Output Alternator

Electrical Load Requirements

Calculate the combined current draw of factory systems and aftermarket components to determine realistic output needs. This helps avoid undersized or oversized alternator selection.

Vehicle Compatibility

Mounting configuration, pulley alignment, and belt capacity must match vehicle specifications to maintain reliable operation and avoid mechanical issues.

Cooling and Duty Cycle

Vehicles operating at idle for extended periods benefit from alternators designed for higher idle output and improved thermal control.

中文简体

中文简体 Español

Español Français

Français