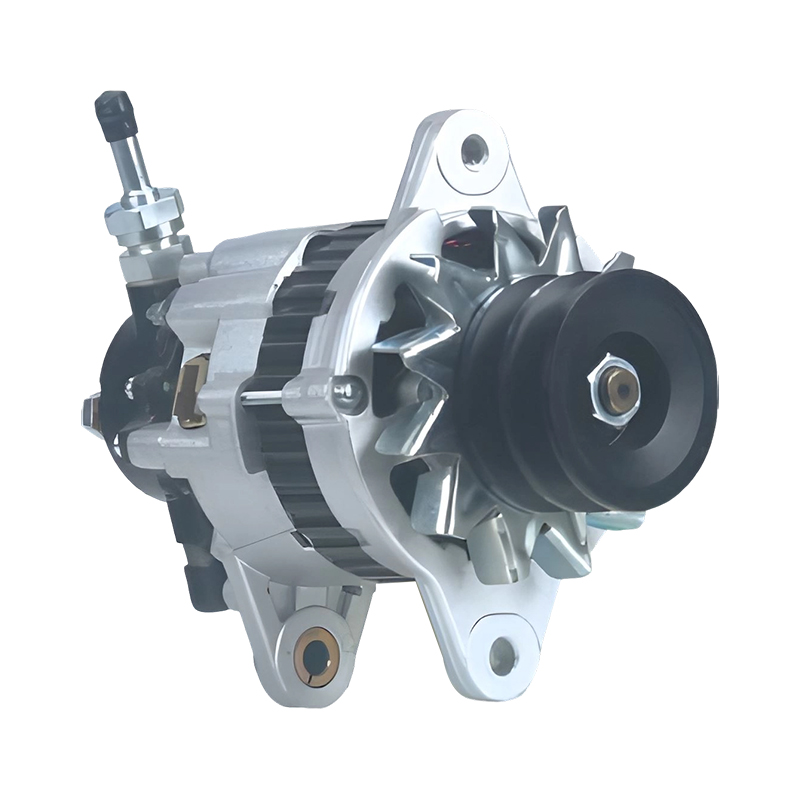

The 12V 250A 1042106860/22949466 DENSO car alternator for Chevrolet Truck Silverado 1500 V6 4.3L is a precision-engineered replacement part specifically designed for the Chevrolet Truck Silverado 1500...

See DetailsWhat Makes a Heavy Duty Truck Alternator Suitable for High-Load Electrical Systems

Dec 11, 2025

Heavy-duty truck electrical systems power a mix of continuous and intermittent high-current equipment: engine control electronics, long-haul telematics, HVAC and refrigeration units, powerful inverters for tools, hydraulic pumps and winches, and work lights. This article examines the concrete design, electrical and mechanical features that make a heavy duty truck alternator suitable for sustained high-load operation, and gives practical guidance for sizing, installation and maintenance.

Understanding heavy-duty electrical loads and operating duty

High-load systems differ from passenger-vehicle electrical systems in two key ways: they present higher continuous current demand and have a wider variety of duty cycles (continuous, duty-limited, and short bursts). Correctly matching a heavy duty truck alternator requires identifying each load’s steady-state current, peak/starting current, expected run-time and whether the load is critical during engine idle or only while driving.

Typical load types and characteristics

Common heavy-duty loads include auxiliary inverters for power tools, refrigeration compressors on refrigerated trailers, hydraulic pumps driven by electrically controlled clutches, large HVAC blowers, winches, heavy lighting banks used for work sites, and increased telematics and safety electronics. Some loads draw high current only during start-up; others draw continuous current for hours. Document each load with typical amperage and duty cycle to determine how the heavy duty truck alternator must respond to these operating patterns.

Representative load comparison (example)

| Load | Typical continuous draw (A) | Duty note |

| Exterior and work lights | 20 | Continuous |

| HVAC blower | 30 | Continuous |

| Trailer refrigeration compressor (electric control) | 60 | Duty-limited |

| Inverter for power tools | 100 | Continuous or intermittent |

| Telematics and auxiliary ECUs | 15 | Continuous |

| Auxiliary winch (intermittent high current) | 150 | Short bursts |

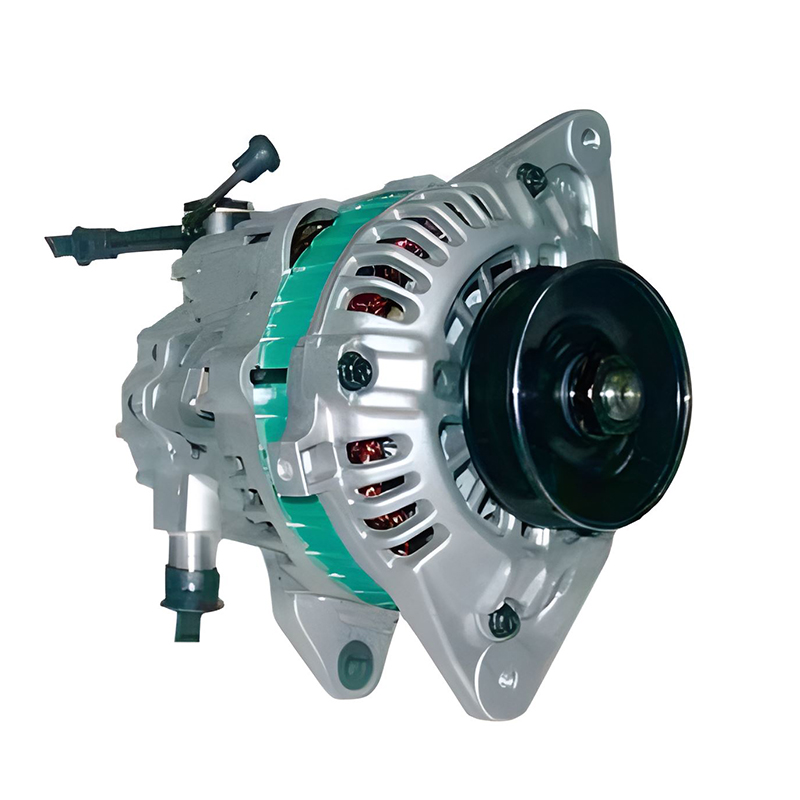

Core alternator design features that enable high-load performance

A heavy duty truck alternator must combine electrical capability with thermal and mechanical robustness. Below are the concrete design elements that determine whether a high-output heavy duty truck alternator will handle demanding electrical loads reliably.

High continuous amperage rating and thermal margin

Look beyond nominal peak amperage. For a heavy duty truck alternator, the actual continuous (rated) amperage at a specified ambient temperature and RPM is the decisive number. A unit rated for higher continuous output will have larger copper cross-sections, higher-grade insulation, and a cooling path designed to evacuate heat over prolonged operation. Verify the continuous rating at idle RPM if the truck spends long periods idling.

Robust cooling: forced air, oil-cool or hybrid

Cooling determines how long the alternator can sustain high current. A heavy duty truck alternator often employs:

- Large internal axial or radial fans sized to move sufficient airflow at low engine speeds.

- External fins and housings designed to improve convective heat transfer for heavy duty alternator for trucks.

- Oil-cooled or coolant-jacketed designs for very high continuous output requirements.

Heavy-duty electrical components and protection

Key electrical robustness measures for a heavy duty truck alternator include oversized diodes and rectifier blocks rated for continuous high currents, high-temperature stator windings with class H or class F insulation, over-temperature sensing, and reinforced solder joints. Many designs add diode heat sinks and upgraded protection against transient voltage spikes.

Advanced voltage regulation and control strategies

High-load systems benefit from smart regulation: multi-stage regulators, CAN-controlled regulators, or externally mounted regulators that allow setpoints to be adjusted for battery conditioning or load limiting. Tight voltage regulation within a heavy duty truck alternator prevents overcharging sensitive electronics and supports stable power distribution.

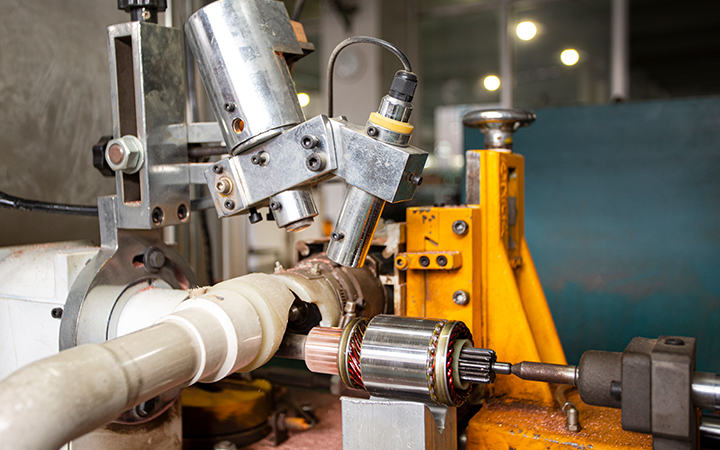

Mechanical durability: bearings, shafts and mounting

A heavy duty truck alternator uses shielded, grease-packed roller or ball bearings sized for radial and axial loads from belt tension and engine vibration. The drive shaft and pulley interface must tolerate torsional shocks from starter engagement and accessory loads. Properly designed mounting flanges and serviceable bearings extend service intervals.

How to size and select an alternator for a specific high-load system

Sizing is a pragmatic engineering exercise: add up expected continuous loads, account for peak/start currents, then add margin for future growth. The same method applies when selecting a high-output heavy duty truck alternator for a modern fleet vehicle.

Step-by-step sizing approach

1) List every electrical component that will run while the engine is on and record its typical continuous current draw.

2) For intermittent high-current devices, estimate an average equivalent continuous draw for duty cycle, or treat them as short-duration design events the heavy duty truck alternator must support.

3) Sum continuous currents and apply a safety margin—commonly 25–35%—to account for aging, temperature, and future accessories.

4) Choose the heavy duty truck alternator with a continuous output rating at or above the computed required current.

Worked example and calculation

Example continuous loads total 375 A (20 + 30 + 60 + 100 + 15 + 150 = 375 A). Applying a 30% margin gives 487.5 A. A 500 A continuous-rated heavy duty truck alternator is appropriate for providing safe margin and accommodating brief surges.

Integration considerations: batteries, belts and system management

Selecting a high-output heavy duty truck alternator is only part of the solution. Supporting systems must be sized correctly to enable reliable charging and stable power supply.

Battery bank and cabling

Use batteries and cabling rated for the expected charging currents. Heavy gauge cabling and low-resistance connections minimize voltage drop; undersized cables stress both the battery bank and the heavy duty truck alternator. Parallel battery banks with isolators help when accessories must run with the engine off.

Belt drive and pulley sizing

Ensure the belt and pulley system can transmit the alternator’s torque at low idle without slip. High-output heavy duty truck alternators draw more torque; multi-groove belts, upgraded tensioners, or revised pulley ratios may be necessary.

Charging strategy and ECU coordination

When present, ECU or CAN-bus control of the alternator regulator allows boost charging, battery conditioning profiles or load limiting strategies to protect the heavy duty truck alternator from prolonged overload. Smart control reduces thermal stress and extends service life.

Maintenance, diagnostics and service life extension

Planned maintenance prevents the heavy duty truck alternator from becoming a single point of failure in fleet applications. Routine inspection and thermal management significantly extend its lifespan.

Routine inspection checklist

- Check belt condition and tension regularly; replace damaged belts to avoid alternator under-speed conditions.

- Inspect electrical connections for corrosion or looseness; measure voltage drop that may reduce heavy duty truck alternator efficiency.

- Load-test the heavy duty truck alternator under real or simulated conditions; verify continuous rated output at low idle.

- Use infrared thermography to locate hot diodes, stressed windings or thermal bottlenecks.

Common failure modes and remedies

Frequent causes of heavy duty truck alternator failure include diode overheating, insulation breakdown from thermal cycling, bearing wear due to belt tension, and regulator faults. Remedies involve proper cooling, correct mounting, adequate wire sizing, and protecting the alternator from continuous overload through good system design.

Practical procurement checklist for choosing a heavy-duty alternator

When evaluating suppliers, use this checklist to confirm the heavy duty truck alternator meets real-world fleet requirements.

- Verify continuous current rating at the lowest expected operating RPM and ambient temperature.

- Confirm thermal performance and cooling method for sustained heavy-load operation.

- Request vibration and shock test reports relevant to heavy-duty truck use.

- Ensure compatibility with the electrical architecture and mounting layout of the target truck model.

- Check warranty coverage for continuous-duty applications and availability of service parts.

Selecting a heavy duty truck alternator for high-load applications requires a data-driven approach: quantify loads and duty cycles, choose an alternator with appropriate continuous output and cooling capability, integrate batteries and cabling correctly, and maintain the system through routine inspections. These engineering measures extend service life and ensure reliable power delivery in demanding fleet environments.

中文简体

中文简体 Español

Español Français

Français